A shark bite fitting is a type of compression fitting used to join two pieces of tubing. It is often used in plumbing applications but can also be found in other settings, such as in the HVAC industry. If a shark bite fitting needs to be removed and no tool is available. In this article, we will describe some easy methods how to remove shark bite fitting without tool.

What Are Shark Bite Fittings?

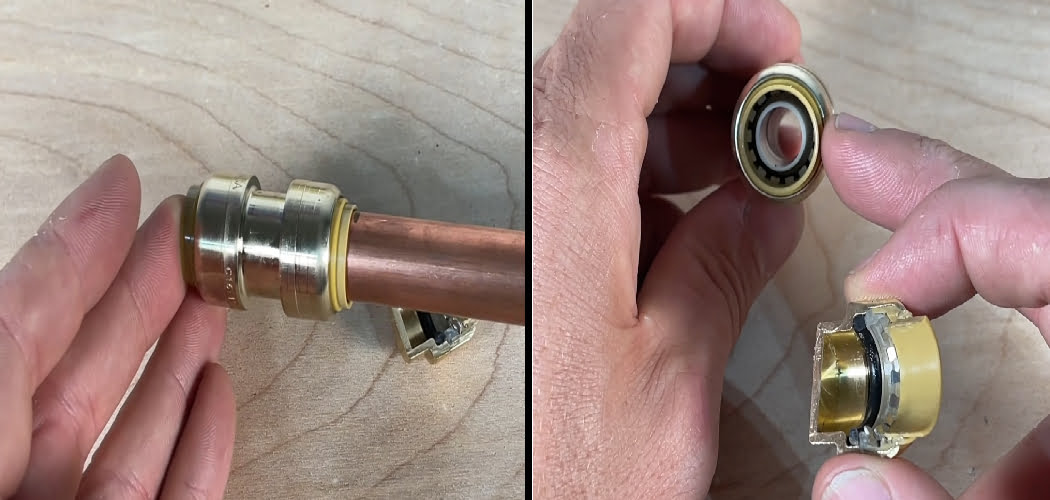

Shark bite fittings are a type of fitting that is used to connect two pieces of tubing. They are often used in plumbing applications but can also be used in other applications, such as HVAC. Shark bite fittings are made up of two pieces: a compression fitting and a connector. The compression fitting is the part that is attached to the tubing, and the connector is the part that is inserted into the compression fitting.

Preparation

To properly remove a shark bite fitting without the proper tool, one must first make preparations. First, one should gather all necessary supplies, including the shark bite fitting removal tool (if available), a bucket or container to catch any water that may leak from the pipe, and a rag to clean up any water or debris. Once everything is gathered, the next step is to shut off the water supply to the pipe.

How to Remove Shark Bite Fitting Without Tool

Follow the methods discussed below to remove shark bite fitting without a tool:

Method 1: Use a Pair of Pliers.

To remove a shark bite fitting using a pair of pliers, one needs to grasp the shark bite fitting with the pliers and twist it in a counterclockwise motion. It is important to ensure that one has a good grip on the fitting before twisting, as it can be difficult to remove if it is stuck. If the fitting does not come loose after a few twists, it may be necessary to use some force to get it unstuck.

Method 2: Hacksaw Blade.

To remove a shark bite fitting, one would use a hacksaw blade to cut through the metal around the fitting. The hacksaw blade is inserted into the opening of the fitting and then sawed back and forth until the metal is cut. Once the metal is cut, the fitting can be removed by pulling it out of the pipe.

Method 3: Chisel and Hammer.

Use a chisel and hammer to remove the shark bite fitting. Place the chisel on top of the shark bite fitting and hit it with the hammer. This will loosen the shark bite fitting and allow you to remove it from the pipe.

Method 4: Flathead Screwdriver.

The shark bite fitting can be removed with a flathead screwdriver by inserting it into the fitting and turning it counterclockwise. If the fitting is stuck, it can be loosened by using a pair of pliers to grip the hex nut on the outside of the fitting and turn it counterclockwise.

Method 5: Pipe Thread Compound.

There are a few ways to remove a shark bite fitting: using a pipe wrench, a strap wrench, or a socket wrench. If the fitting is corroded, it may be necessary to use a pipe thread compound to help loosen it. First, make sure the water is turned off, and the fitting is dry. Apply the pipe thread compound to the threads of the pipe and screw the fitting in place.

Method 6: Use a Utility Knife.

The first step is to cut the shark bite fitting off as close to the pipe as possible with a utility knife. If there is any excess pipe after the shark bite fitting has been cut off, it should be removed using a pipe cutter. Next, the threads on the end of the pipe should be cleaned up using a wire brush. Finally, a new shark bite fitting can be attached by following these same steps in reverse.

Method 7: Wrench.

Shark bite fittings are a popular type of fitting for water pipes due to their easy installation and leak-free performance. However, if a shark bite fitting needs to be removed, it can be a challenge, as the fitting is designed to create a watertight seal. A wrench is the best tool for removing a shark bite fitting. First, find the correct size wrench that fits the nut on the shark bite fitting.

Precautions

When removing a shark bite fitting without a tool, be sure to take the following precautions:

1. Make sure the shark bite fitting is completely unscrewed before removing it from the pipe.

2. Use a cloth to hold onto the shark bite fitting while unscrewing it to avoid getting your hands dirty.

3. Be careful not to lose the O-ring that seals the shark bite fitting to the pipe.

Conclusion

In conclusion, there are several ways to remove a shark bite fitting without a tool. The easiest way is to use a pair of pliers. If you don’t have pliers, you can use a screwdriver or a knife. However, be careful not to damage the fitting or the pipe. Finally, always make sure the water is turned off before attempting to remove the fitting.

Frequently Asked Related Questions

How Do You Remove a Shark Bite End Cap?

The process of removing a shark bite end cap begins by identifying the end cap that needs to be removed. Once the end cap is identified, a tool such as a screwdriver is inserted into the opening at the base of the cap. The screwdriver is then used to pry the end cap off of the pipe.

What is the Life Expectancy of a Shark Bite Fitting?

There is no definitive answer to this question. Some factors that would influence a shark bite fitting’s life expectancy include the size and type of Shark, the location of the bite, and the severity of the wound. In general, however, shark bites are considered relatively low risk for infection and typically do not result in long-term health complications.

Are Shark Bite Fittings Permanent?

Shark bite fittings are a type of fitting used in plumbing that allows for a watertight connection between two pipes. The fitting is tightened by hand, and because it is made of a soft material, it can be easily adjusted if it is not quite right. Shark bite fittings are not permanent fixtures; they can be easily removed if necessary.

Do Shark Bites Ever Fail?

Shark bites never fail in the sense that they always puncture and tear flesh. However, they may not always be successful in terms of causing significant injury to their prey. Sharks have been known to consume prey that was much too large for them, resulting in the Shark becoming injured or even dying as a result.

Does Shark Bite Fittings Leak Over Time?

There is no definitive answer to this question as it depends on a number of factors, including the type of shark fitting used, the age of the fitting, and the environmental conditions to which it is exposed. In general, however, shark fittings are considered reliable and durable and should not leak over time if properly installed and maintained.

Should I Sand Copper Pipe Before Shark Bite?

There is no definitive answer to this question, as the best practice for sanding copper pipe before shark bite fittings depend on a variety of factors, such as the type of copper pipe, the size of the shark bite fittings, and the degree of rust and corrosion on the copper pipe. In general, however, it is usually recommended to the sand copper pipe before installing shark bite fittings in order to create a smooth surface that will be less likely to cause leaks.

Is It Ok to Use Shark Bite Fittings on Walls?

The simple answer to this question is: it depends. It depends on a variety of factors, including the type of wall, the type of fitting, and the thickness of the wall. In general, Shark bite fittings are a good option for walls that are thin enough that they can be easily penetrated by the fitting. However, if the wall is too thick, the fitting may not be able to go all the way through, which could cause problems.

Does Shark Bite Need Teflon Tape?

The quick answer to this question is no; shark bite does not need Teflon tape. However, the more detailed answer depends on several factors.

Teflon tape is a type of adhesive tape that is used to create a watertight seal around threaded fittings. It is made of a polymer called PTFE, which stands for polytetrafluoroethylene. This material is known for its ability to resist heat, chemicals, and corrosion.